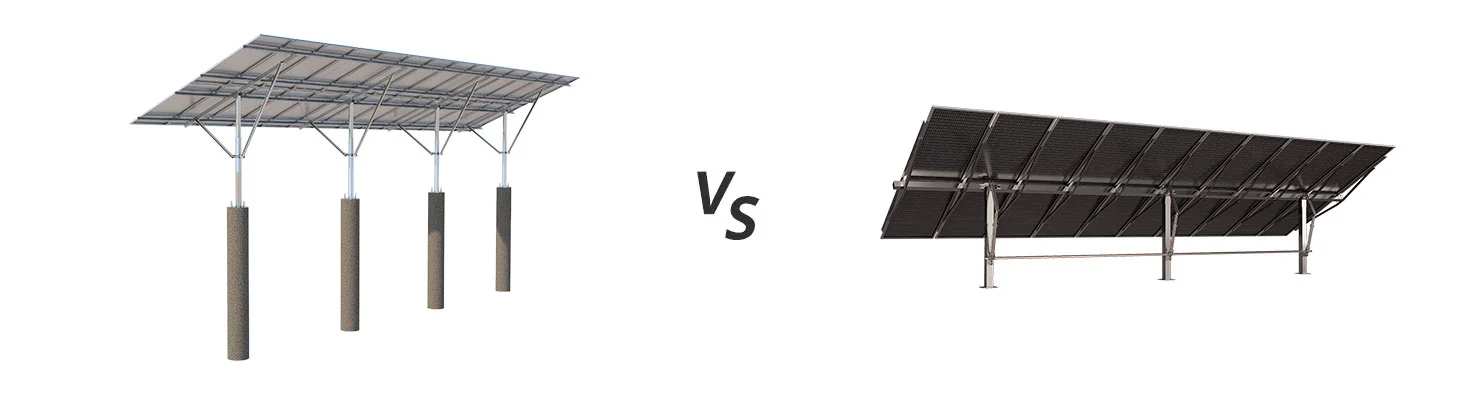

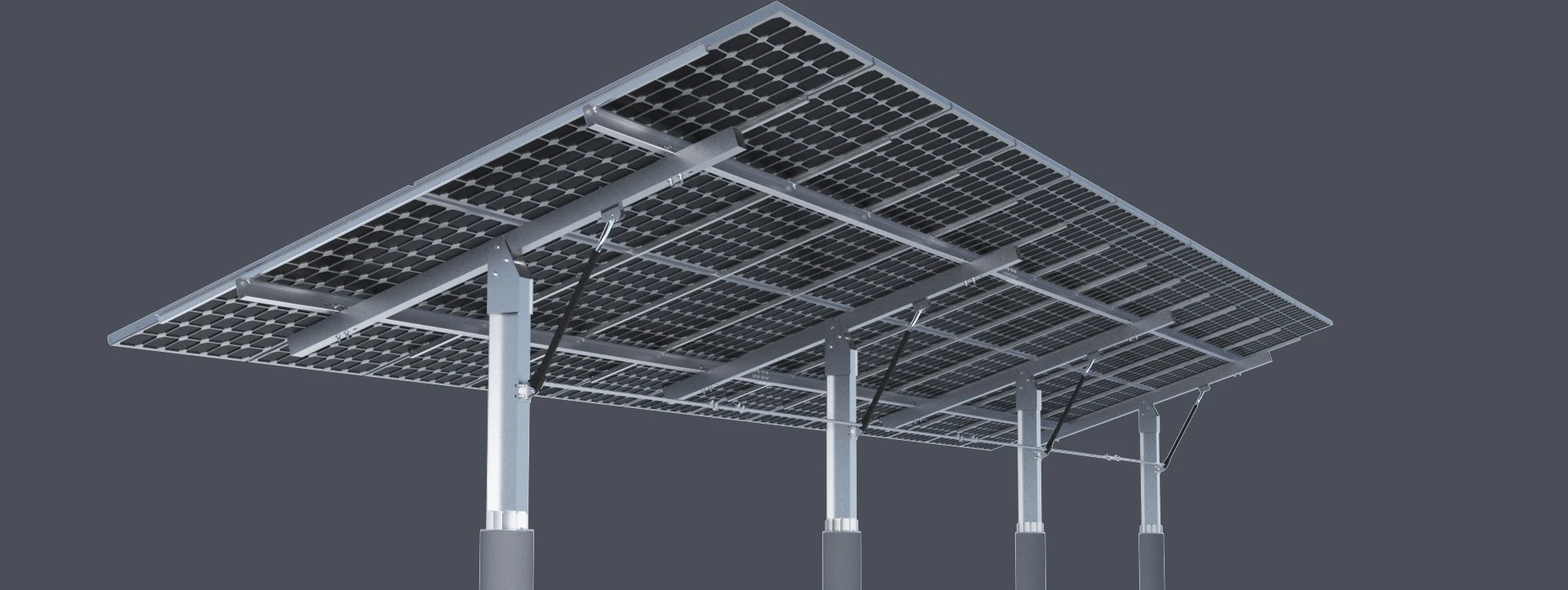

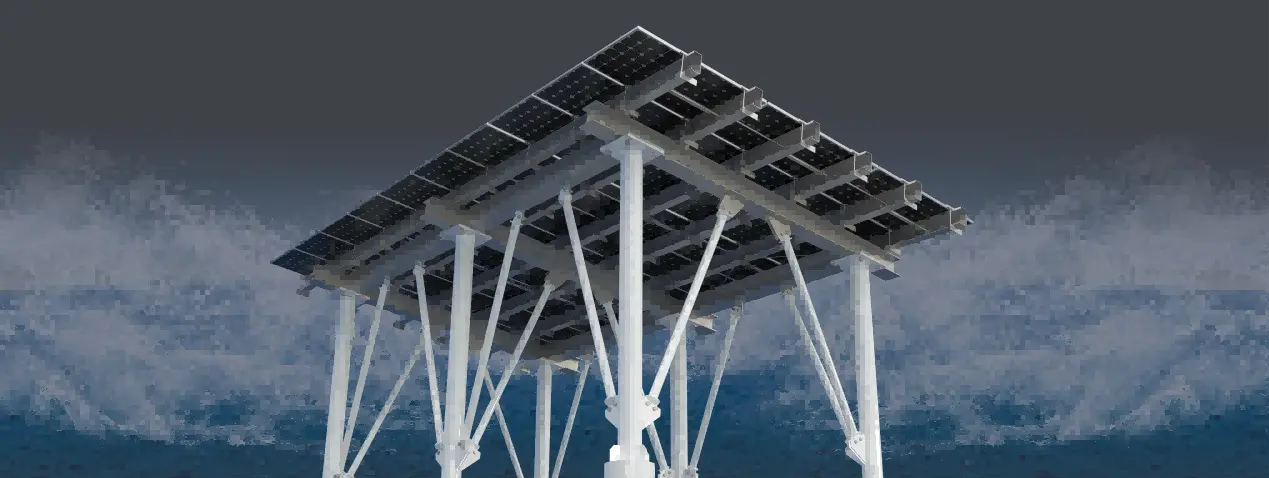

Independent Horizontal Single-axis Tracker

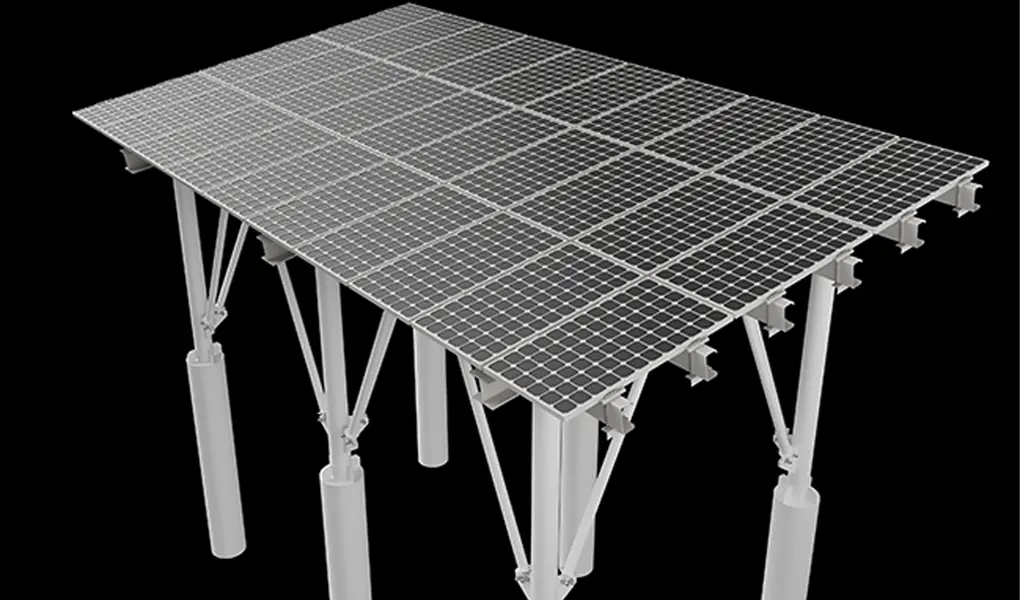

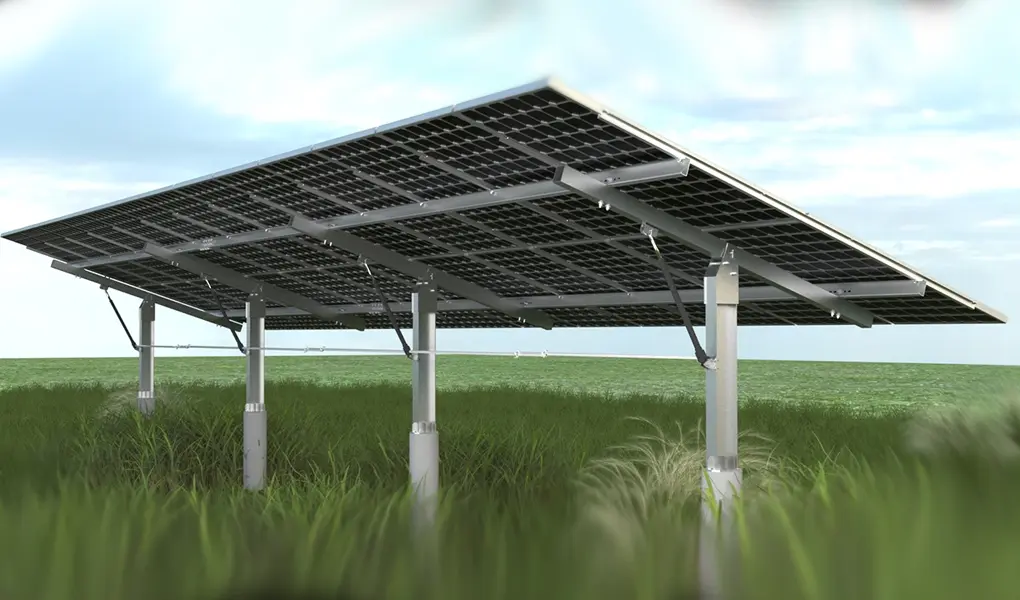

The horizontal single-axis tracker has an automatic adjustment function and can adjust its angle in real time according to the position of the sun to ensure optimal lighting. Engineered with precision and featuring an independent horizontal single-axis design, our horizontal single-axis solar tracker is set to become an industry standard, providing unmatched flexibility and scalability for solar projects of all sizes. We are committed to providing high-quality, reliable and easy-to-install horizontal solar tracker systems to help you maximize your solar power generation efficiency.

CN

CN JP

JP